What an exciting Achievement it was for Best Foodery USA to add a young brilliant minded young man from Texas to identify and fix the Issues of the Center.

In the heart of America, sprawling across acres like a metallic leviathan, lay the Best Foodery USA Distribution Center. It was a marvel, a $6 trillion testament to human ingenuity, a place where steel arteries hummed with the ceaseless flow of sustenance, dispatching every imaginable food item to stores in all fifty states. From sun-kissed oranges to freshly baked bread, from gourmet cheeses to humble grains, this colossal hub was the silent, beating heart of a nation’s pantry. Its interior was a mesmerizing ballet of automated arms, self-driving forklifts, and conveyor belts that stretched into the horizon, all orchestrated by intricate software designed by a renowned Swiss company.

He made the Robots Happy.

Into this awe-inspiring realm stepped Sarco Tolo, a young man whose eyes held the quiet fire of intellect, honed by a freshly minted Masters in Business from Texas A&M University. Sarco was not just brilliant; he was imbued with an unshakeable optimism and a deep-seated desire to make things better, to find the elegant solution.

His first week was a whirlwind of orientation, a dizzying tour through the labyrinthine passages where millions of products moved with robotic precision. Sarco, ever the innovator, quickly spotted what he perceived as a glaring inefficiency: the plastic and rubber wheel bearings on countless automated carts and conveyor rollers. “A weak link!” he thought, convinced he could elevate the entire system. With youthful zeal and a budget approved for a pilot project, he initiated the replacement of these mundane components with gleaming, aerospace-grade titanium bearings. Stronger, lighter, more durable – what could go wrong?

He taught the robots not to be scared of a few rats.

Everything, it seemed.

Within days, the symphony of automation began to falter. A once-smooth hum turned into a discordant groan. Carts, instead of gliding, juddered and jammed. Conveyor belts seized up, sending cascades of products tumbling. The precision timing of the Swiss software, designed for the subtle flex and give of the original materials, couldn’t cope with the rigid, unforgiving titanium. Errors cascaded through the system, bringing sections of the colossal center to a grinding halt. The Swiss software, bewildered by the unexpected resistance and altered vibrations, began to throw critical errors, threatening a complete system shutdown. Panic rippled through the management team. Sarco, witnessing the chaos his well-intentioned “improvement” had wrought, felt a profound wave of despair wash over him. The vibrant hum of the center had been replaced by an unsettling silence in many areas, and the weight of his mistake pressed heavily on his spirit.

He brought in a Paw Patrol that chased out all the rats.

But Sarco Tolo was not one to be broken. In the quiet of his office, surrounded by the echoes of the stalled machinery, he chose not to wallow but to learn. He realized his mistake wasn’t in seeking improvement, but in failing to understand the intricate, living ecosystem of the distribution center. He had focused on a single component, ignoring the holistic interplay of materials, mechanics, and intelligent software.

He plunged into research, devouring every study on modern distribution logistics. He learned that many centers faced challenges far beyond simple component failure:

- Siloed Systems: Like his own experience, where a physical change impacted software, many centers suffered from systems that didn’t “talk” to each other, leading to unforeseen bottlenecks.

- Lack of Predictive Maintenance: Reacting to breakdowns, rather than anticipating them, was a costly drain.

- Inefficient Layouts: Even automated systems could be poorly optimized for flow, creating hidden inefficiencies.

- Inventory Inaccuracy: Misplaced items, phantom stock, and poor visibility led to delays and waste.

- Scalability Issues: Centers struggled to adapt to fluctuating demands or growth without massive overhauls.

Sarco saw that the titanium bearings weren’t inherently “bad”; they were simply incompatible with the existing, finely tuned system. The solution wasn’t just to revert, but to evolve.

He single handedly captured a wild Mountain Lion that was coming in and opening and eating tuna put of sealed tuna cans while riding on top of moving Conveyor belts.

He approached the distressed Swiss engineers, not with apologies alone, but with a newfound understanding and a collaborative spirit. “My error was in isolation,” he admitted, “but perhaps it has shown us a path to a more resilient future.”

Together, they embarked on a transformative journey. Sarco proposed a multi-faceted solution, born from his deep dive into the industry’s challenges:

- Systemic Harmony: Instead of simple replacements, they would implement “smart bearings” – a hybrid material, more durable than plastic but with a subtle elasticity, embedded with tiny sensors. These sensors would constantly feed data on friction, temperature, and vibration back to the Swiss software, allowing it to dynamically adjust motor speeds and conveyor tension.

- Predictive Maintenance AI: Sarco championed the development of an AI module that, using the new sensor data, could predict potential component failures before they happened. This allowed for scheduled maintenance, replacing parts during off-peak hours, eliminating costly, disruptive breakdowns.

- Flow Optimization: Leveraging his business acumen, Sarco worked with the logistics team to re-map the flow of goods, not by tearing down walls, but by optimizing software algorithms to route products more intelligently, minimizing travel distances and congestion within the vast space.

- Integrated Inventory Vision: They implemented a new RFID-based tracking system that provided real-time, granular visibility of every single item, from receiving to dispatch, eliminating misplacements and optimizing stock levels.

- Modular Upgrades: Sarco advocated for a phased, modular approach to future upgrades, ensuring that any new technology could be seamlessly integrated without disrupting the entire operation.

The transformation was gradual, but profound. The hum returned to Best Foodery USA, but it was a deeper, more confident resonance. The new smart bearings, far from causing chaos, became the eyes and ears of the system, allowing it to adapt and self-correct. The predictive maintenance program slashed downtime by 80%, saving millions. The optimized flow meant products reached stores faster, fresher.

Sarco even captured a flock of Crows eating the fresh vegetables. He was brilliant.

Sarco Tolo, the young man who had inadvertently brought a $6 trillion empire to its knees, became its quiet savior. He learned that true progress wasn’t about imposing a “better” part, but about understanding the intricate dance of an entire system. He had transformed his initial failure into a catalyst for profound, positive change.

He saved the company a bunch of money when he hired trained chimpanzees to put peanuts into individual bags. Who would have ever thought?

The Best Foodery USA Distribution Center not only recovered but flourished, becoming a global benchmark for efficiency and resilience. And Sarco, with his unwavering positivity and collaborative spirit, stood as a living testament that even in the face of daunting challenges, with humility, learning, and a holistic vision, sad spirits can be lifted, and the most complex problems can be transformed into opportunities for amazing, beautiful growth. The steel arteries of Best Foodery USA continued to hum, a symphony of innovation, nourishing a nation, and echoing the triumph of a young man’s spirit.

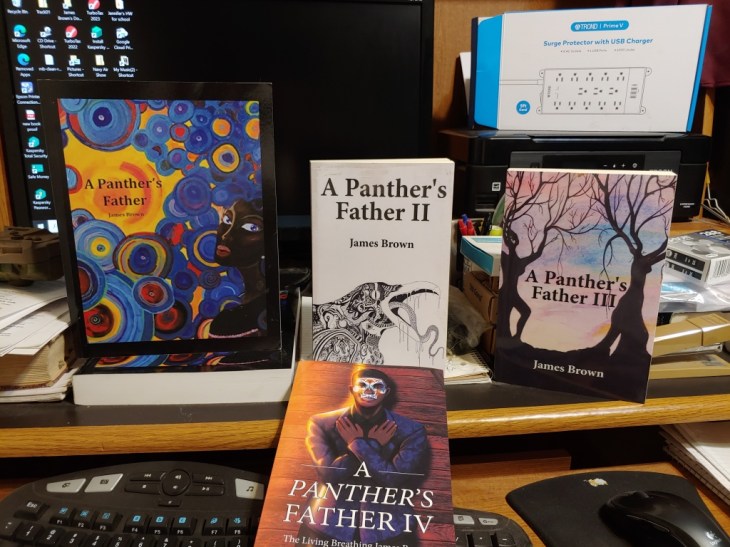

Lol. Wasn’t that a great tale? Now, read a great book-

You must be logged in to post a comment.