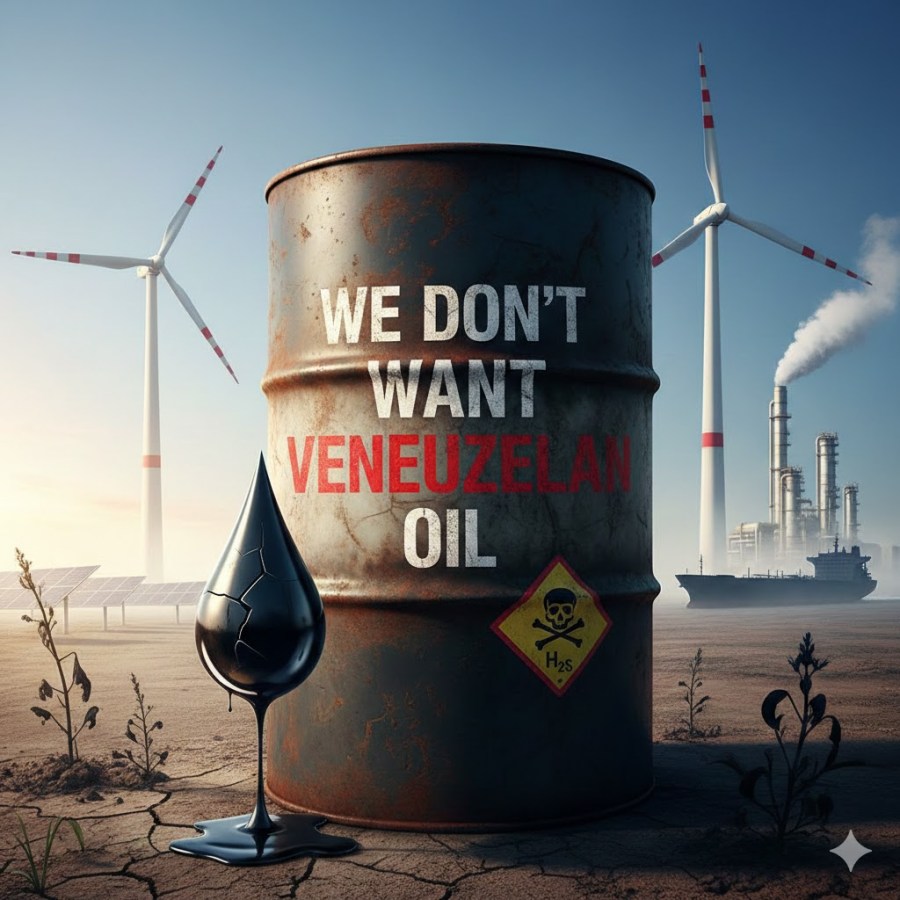

Heavy in H2S is not a funny subject. One breath and YOU DIE! America does not want or need Venezuela H2S Crude. Tell the Oil Companies to stay away from VENEZUELA Crude. We don’t need it.

The Strategic and Operational Liability of Venezuelan Heavy Sour Crude

For decades, the global energy market has relied on a variety of crude oil grades to meet industrial demand. However, as the American energy landscape shifts toward efficiency, environmental responsibility, and infrastructure longevity, the case for importing high-sulfur, extra-heavy crude—specifically from regions like Venezuela’s Orinoco Belt—has collapsed.

Between its hazardous chemical profile and its physical resistance to refining, this “sour” oil is an archaic resource that the United States neither needs nor wants.

1. The Chemistry of Risk: Hydrogen Sulfide ($H_2S$)

Venezuelan crude is notoriously “sour,” with sulfur content often reaching between 4% and 5.7% by mass. The primary concern isn’t just the sulfur itself, but its transformation into Hydrogen Sulfide ($H_2S$).

- Toxicity: 1$H_2S$ is a potent neurotoxin.2 Even at low concentrations, it poses a lethal risk to workers at extraction sites and refineries.3+1

- Corrosivity: Known as “sulfide stress cracking,” 4$H_2S$ aggressively attacks steel.5 Utilizing this oil requires constant, expensive monitoring of pipelines and storage tanks to prevent catastrophic leaks.

- Environmental Burden: Removing sulfur to meet EPA standards requires intensive hydrotreating, which increases the carbon footprint of the refinery itself.

2. The Refining Bottleneck: “Cracking” the Heavy Ends

Beyond its chemical toxicity, Venezuelan oil is physically “heavy.”6 It possesses high viscosity and a high concentration of long-chain hydrocarbons, making it resemble molasses or liquid asphalt more than traditional light sweet crude.

| Feature | Light Sweet Crude (Preferred) | Venezuelan Heavy Sour |

| Viscosity | Low (flows easily) | High (requires heating/diluents) |

| API Gravity | > 30° | < 10° (Extra-Heavy) |

| Yield | High Gasoline/Diesel yield | High Residual/Asphalt yield |

| Processing | Simple Distillation | Complex Coking/Cracking |

Refining this oil requires delayed coking units and fluid catalytic crackers (FCC) to work at maximum capacity just to “break” the thick molecules into usable fuel.7 This puts immense mechanical strain on American refineries, increasing downtime and maintenance costs.

3. Economic and Geopolitical Redundancy

The argument that the U.S. “needs” this oil is an artifact of the 1990s. The Shale Revolution has fundamentally altered American energy security.

- Domestic Abundance: The U.S. is now a leading producer of light, sweet crude. Our domestic product is cleaner, safer to handle, and requires far less energy to refine into high-quality gasoline.

- Infrastructure Misalignment: While some Gulf Coast refineries were originally configured for heavy crude, the capital cost of maintaining those “sour” lines outweighs the benefit when compared to the declining costs of processing cleaner domestic or North Sea grades.

Conclusion

Venezuelan heavy sour crude represents a bygone era of energy dependence. Its high $H_2S$ generation creates a hazardous environment for the American workforce, and its physical density creates an inefficient bottleneck in our refining infrastructure.

In an era prioritizing “green” refining and worker safety, there is no logical place for an oil that is as difficult to crack as it is dangerous to breathe. America’s energy future lies in the light and the clean—not the heavy and the sour.

You must be logged in to post a comment.